Consistent quality management

per IATF 16949

We implement a certified quality management system per DIN ISO 9001 and IATF 16949. We therefore additionally we meet the highest quality standards of the automotive industry. This guarantees the constant high quality of our products to our customers. Our excellent flexibility and speed are our strengths.

Excellent customer satisfaction in terms of quality is shown by our customers' quality assessment as an A-list supplier. We achieve this by continuously focusing our internal processes and our quality management system on the needs of our customers.

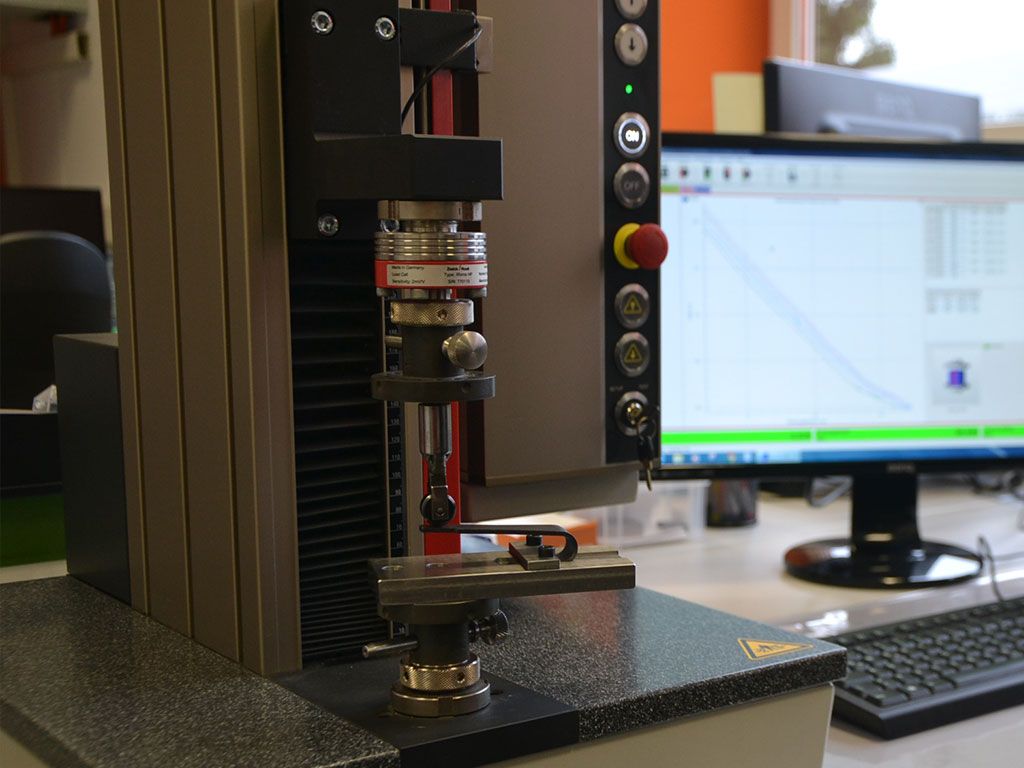

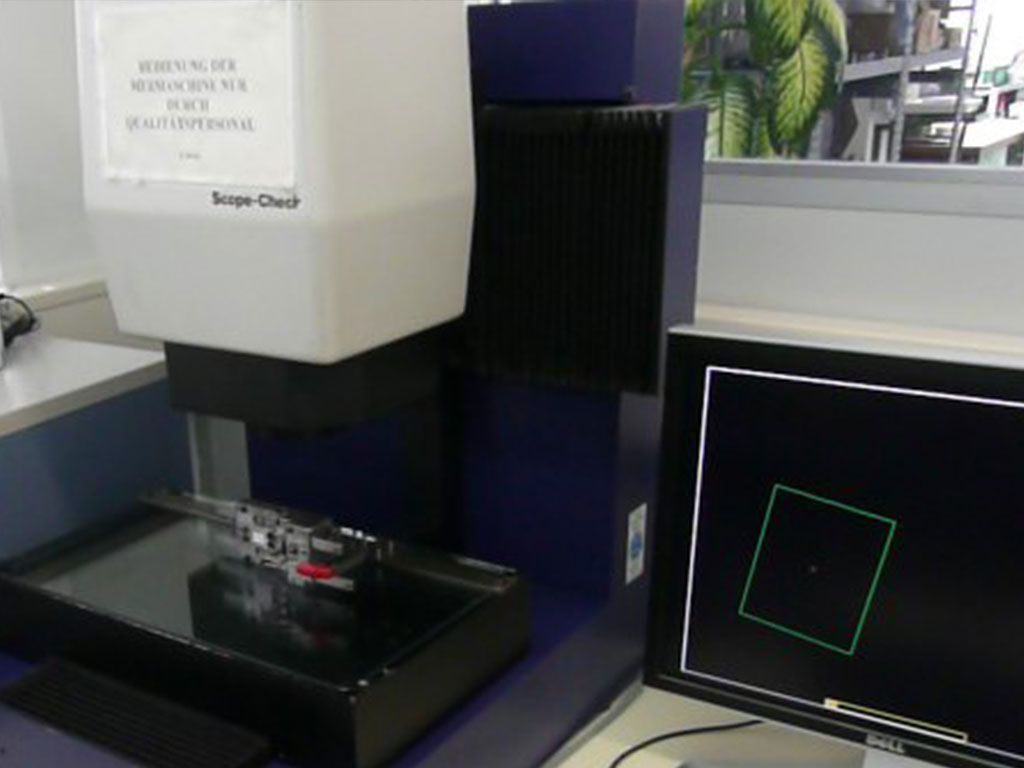

To monitor processes, over and above conventional measuring equipment for the rational measuring of workpieces, our employees have an optical CNC measuring machine, spring force measuring and profile projectors with comprehensive 2D and 3D analysis. And of course statistical results are also available to document and control the processes.

In addition to conventional measuring equipment, our employees mainly use digital optical measuring technology (Keyence, Werth, Mitutoyo, ...) for the rational measurement of workpieces for process monitoring. Optical profile projectors and machines for optical CNC measurement and spring force measurement (Zeiss) are used with the possibility of extensive 2D and 3D evaluations.

Of course, a modern CAQ system from Böhme and Weihs with a wide range of statistical evaluation options is available for controlling the processes. All production departments have digital optical measurement stations with CAQ data acquisition and analysis tools connected online to quality management and production control. As a result, our processes are constantly monitored and employees receive real-time direct feedback on the quality of currently produced products.